History

A STORY OF STEEL

FOR OVER 50 YEARS

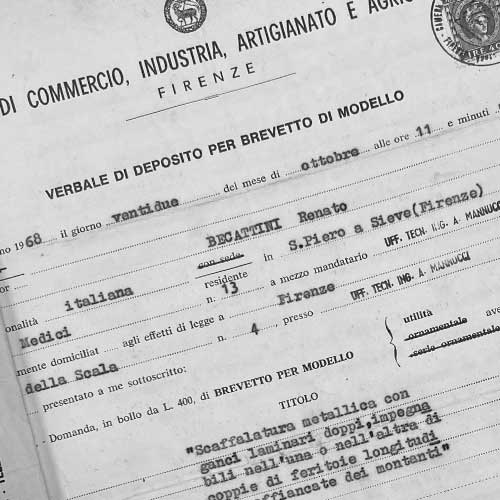

1968

The foundation

The foundation

Renato Becattini patents a new hook shelving system. Updated over the years, it is still excellent today in terms of functionality and reliability. Together with other partners, Renato founded Etermet sas in an agricultural warehouse on the hills of Florence.

1972

The first production laboratory

The first production laboratory

Etermet SaS moves its production laboratory to Calenzano, in via Vittorio Emanuele 50.

1977

Etermet by Becattini Renato

Etermet by Becattini Renato

Renato acquires the shares of the other partners and the company becomes family-run.

1980

The first powder coating plant

The first powder coating plant

Etermet is among the first companies in the sector to focus on the quality of painting. In 1980, an automatic powder coating system was purchased, thus paving the way for an innovation that would also inspire other companies in the sector in the following years.

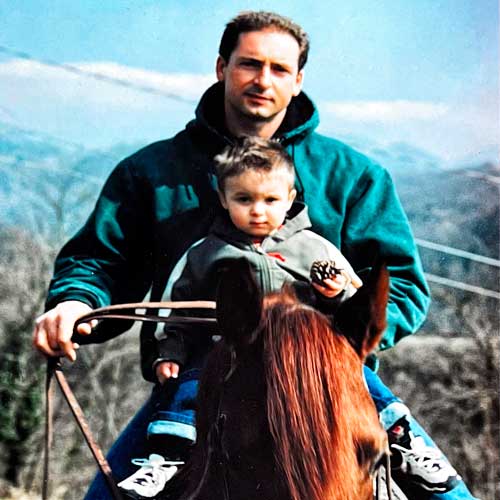

1992

Etermet snc

Etermet snc

It is the year of generational succession in which his son Fabrizio Becattini acquires the majority of the company and becomes the driving force of the business.

2000

Expansion

Expansion

Thanks to the good results obtained, the production space was doubled by acquiring the adjacent factory.

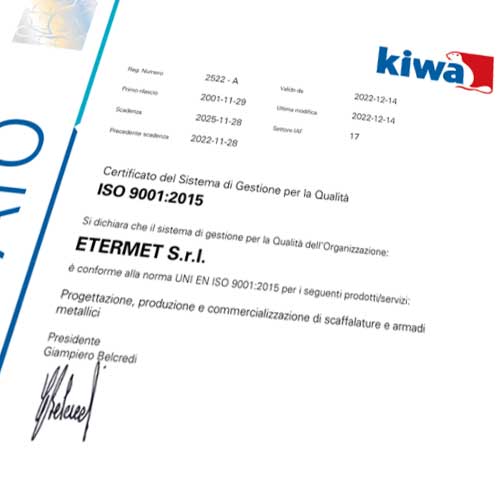

2001

UNI EN ISO 9001 certification

UNI EN ISO 9001 certification

Etermet, which has always been committed to providing high quality products and services that meet the needs and expectations of customers, decides to adapt its business processes to the UNI EN ISO 9001 standard. The objective is to continuously improve operational processes, involve staff at all levels of the organization and ensure compliance with applicable laws and regulations in the industrial racking industry.

2006

Etermet srl and Cisi Quality & Safety brand

Etermet srl and Cisi Quality & Safety brand

Fabrizio takes over the company and starts a process of constant growth by reorganizing the company strategy and renewing products and production lines. It is the year in which the company registered in the Industrial Shelving section of the ACAI (Italian Steel Manufacturers Association), receiving the CISI Quality & Safety mark. Etermet has maintained the brand, which is a guarantee of the application of good technical standards that ensure the suitability of the shelves regulated according to Legislative Decree 172/04 on the "safe product", as long as this has existed and still maintains its production standards adhering to those rules.

2009

Perfect shelf

Perfect shelf

A new hook-shelf-mobile reinforcement system was patented and two automatic lines were subsequently installed for their production.

2012

New headquarters

New headquarters

It is the year of the acquisition of the current factory based in Via di Le Prata, also in Calenzano. The project includes new organized spaces and the installation of a photovoltaic system on the roof which meets more than 60% of the energy needs.

2017

6Strong

6Strong

Etermet installs two automatic Industry 4.0 profiling lines for the production of the new 6Strong anti-seismic shelving system for light and medium-heavy loads. Furthermore, an innovative Industry 4.0 quick color change paint booth is introduced, thus allowing customers to choose from all RAL K7 colours.

2019

Campi Bisenzio production site

Campi Bisenzio production site

On February 20th the new production site in Campi Bisenzio for molding, carpentry and welding processes was inaugurated.

2021

Trenta5

Trenta5

The new light shelving system with Trenta5 closed profile upright is born, which takes the performance of this type of shelving to a higher level. For its production, three new automatic Industry 4.0 production lines are installed.

2023

Re-design of the headquarters

Re-design of the headquarters

With the renovation process of the main factory in Calenzano, which involves the insulation of the roof and facade, the installation of a mechanized brise soleil and a parking area covered by photovoltaic panels and equipped with charging columns, Etermet underlines its continuous commitment to conducting its activities in a sustainable way and promoting environmentally friendly practices.

TODAY

Landmark

Landmark

Today Etermet is a point of reference in Italy for the production of metal shelving for light and medium-heavy loads. Our mission is to assist companies in optimizing their storage space, improving their operational efficiency and ensuring safety in the workplace. We achieve these objectives through the design and production of innovative and reliable products, which represent the perfect synthesis between tradition and innovation. The continuous research on the product and on the production systems, the flexibility, the vast range of solutions and accessories and the rich know-how of our technicians make us unique on the market and allow us to also design "tailor-made" solutions to satisfy the most demanding customers. demanding.